Low loss: Because the Winding Core dry distribution transformer has the characteristics of small joint magnetic resistance, the magnetic circuit of the corner is consistent with the magnetic direction of the silicon steel sheet, the winding tight filling coefficient is high, and the iron core is light. Compared with the traditional stacked core dry transformer, the no-load loss Po can be reduced by 18% to 28%. The no-load current Io drops by 50% to 60%. The energy saving effect is remarkable and the operation is economical.

Low noise: The noise level of the three-dimensional coil core transformer is 5-10 dB lower than that of the stacked iron core transformer. It is 15 to 20 decibels lower than the current professional standard JB/T10088-2004 "6-220kV transformer noise", which is an ideal silent product.

Low partial discharge: The resin mixing material adopts the most advanced mixing method and the vacuum film degassing technology to make the mixture evenly stirred, completely eliminates the bubbles in the middle of the mixture. The high and low pressure coils are all poured under vacuum pressure, and the resin is insulated. It has full encapsulation and is completely impregnated between layers. The partial discharge of the product is controlled below 5PC. The cast body has a dense solidified structure, which is flame retardant, explosion-proof and does not pollute the environment.

High mechanical strength: The three-dimensional coil core adopts a circular core cross section, and the short circuit resistance is better than the long round section. The resin with filler has a small difference in expansion coefficient in the casting body, a small curing shrinkage rate, a small internal stress, and a high hardness of the cured product, and a pre-formed reinforcing material is placed in the epoxy resin encapsulating layer on the inner and outer surfaces of the high and low voltage coils. With a dense structure like reinforced concrete, the mechanical strength is much greater than that of pure epoxy resin, so the product can withstand sudden short-circuit electric power without damage.

| Rated Capacity (KVA) |

Connection Method |

Voltage Combination |

No Load (W) |

Load (W) |

No Load Current (%) |

Impendence Voltage(%) |

||

| HV | Tap range | LV | ||||||

| 30 | Yyn0 Dyn11 |

10 6.3 6 |

±5% ±2×2.5% +3×2.5% -1×2.5% |

0.4 | 150 | 710 | 2.3 | 4 |

| 50 | 215 | 1000 | 2.2 | |||||

| 80 | 295 | 1380 | 1.7 | |||||

| 100 | 320 | 1570 | 1.7 | |||||

| 125 | 375 | 1850 | 1.5 | |||||

| 160 | 430 | 2130 | 1.5 | |||||

| 200 | 495 | 2530 | 1.3 | |||||

| 250 | 575 | 2760 | 1.3 | |||||

| 315 | 705 | 3470 | 1.1 | |||||

| 400 | 785 | 3990 | 1.1 | |||||

| 500 | 930 | 4880 | 1.1 | |||||

| 630 | 1070 | 5880 | 0.9 | |||||

| 630 | 1040 | 5960 | 0.9 | 6 | ||||

| 800 | 1215 | 6960 | 0.9 | |||||

| 1000 | 1415 | 8130 | 0.9 | |||||

| 1250 | 1670 | 9690 | 0.9 | |||||

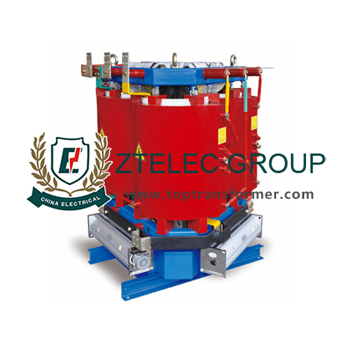

For low-loss transformers, please choose ZTELEC Winding Core dry distribution transformer, a new future for green.

10-30~5000_20 Series Dry-type Transformer.webp)

10, SC(B)11-30~4000_10 Series Dry-Type Transformer.webp)

Leave A Comment