The description of amorphous alloy iron core distribution transformers

Amorphous alloy iron core distribution transformers have high insulation strength, the transformer cores and coils are vacuum-dried and amorphous alloy iron core distribution transformers is assembled using a full vacuum oil injection process. The insulation level of the product has reached a new level. Amorphous alloy iron core transformers have strong short-circuit resistance. Because amorphous alloy cores cannot withstand large pressures, it is difficult to fix the cores and coils in a conventional manner. Our company effectively guarantees the short circuit resistance of the product by adopting special structural design and process methods. Among them, the amorphous alloy double change ratio fully-encapsulated oil-immersed transformer designed and manufactured by our company has passed up to 6 short-circuit tests which proves that the product has extremely strong short-circuit resistance.

The difference between an amorphous alloy iron core distribution transformer and other types of transformers is the no-load loss of the transformer and the no-load loss of the transformer depends on the magnetic permeability of the core material of the transformer. The core of the amorphous alloy iron core distribution transformers uses an isotropic soft magnetic magnetically permeable material-an amorphous alloy. This material has a small magnetizing power, high resistivity, and small eddy current loss. The no-load loss and no-load current of the amorphous alloy iron core distribution transformers core made of amorphous alloy material are very low. The no-load loss is about 75% lower than the no-load loss of the S9 transformer and about 65% lower than the no-load loss of the S11 transformer. , Greatly reducing operating costs, energy saving effect is very significant.

The advantages of amorphous alloy iron core distribution transformers

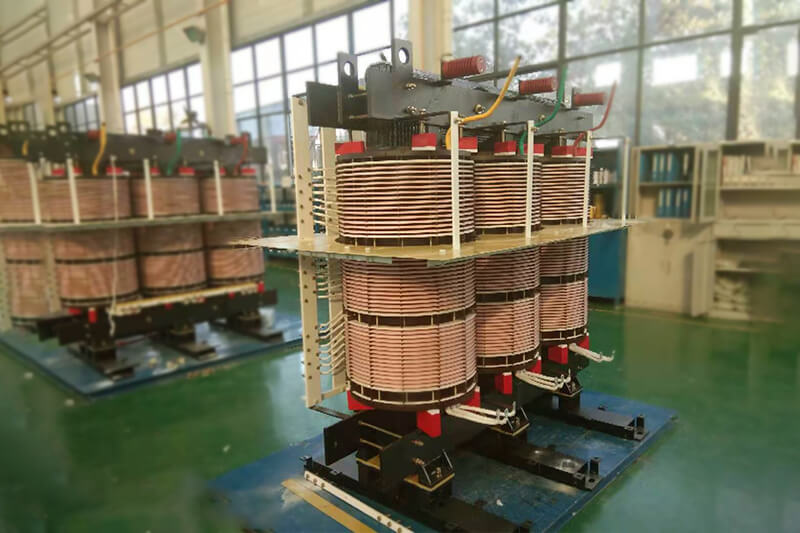

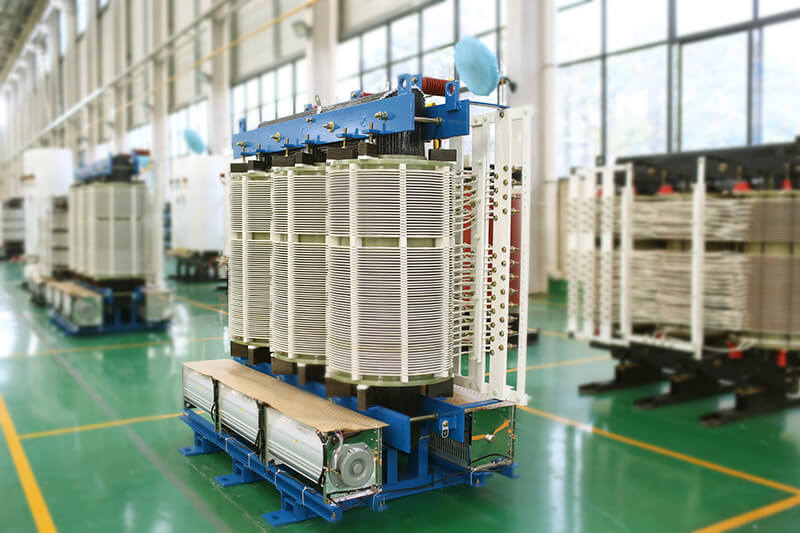

The amorphous alloy iron core distribution transformer produced by our factory is a low-noise, low-loss resin cast-coil dry-type transformer with product model registration. Due to the strict design, materials and formula, the technology and high standards of testing, the product has the following characteristics:

Copper wire for high-voltage coils, copper wire or copper foil for low-voltage coils, epoxy resin cast under vacuum, solidified to form a solid cylindrical body, high mechanical strength, small partial discharge and high reliability.

Flame retardant, explosion-proof and environmentally friendly. Insulation materials of amorphous alloy iron core distribution transformers such as glass fiber wound coils have self-extinguishing properties and no arc will be generated due to short circuit, and the resin will not generate harmful gases under high heat.

The features of amorphous alloy iron core distribution transformers

1. Copper wire for high-voltage winding, copper wire or copper foil for low-voltage winding, glass fiber felt filling and wrapping, casting under vacuum state with unfilled epoxy resin, solidified cylindrical body after curing with small partial discharge and high reliability.

2. Flame retardant, explosion-proof, no pollution to the environment. Insulation materials such as glass fiber wrapped around the coil have self-extinguishing characteristics, and no arc will be generated due to short circuit and the resin will not generate harmful gas under high heat.

3. The coil of amorphous alloy iron core distribution transformer does not absorb moisture, and the core clamp has a special anti-corrosion protection layer which can be operated in 100% relative humidity and other harsh environments. Discontinuous operation is not necessary.

4. High level of resistance to short circuit and lightning.

5. The resin layer inside and outside the coil is thin and the heat dissipation performance is good. The cooling method generally uses natural air cooling. For any protection level transformer, air cooling system can be configured to improve short-term overload capacity and ensure safe operation.

6. Small size, light weight, small floor space, low installation cost, no need to consider oil drainage ponds, fire protection facilities and backup power.

7. Low loss, good power saving effect, economic operation, and maintenance-free.

8. Because amorphous alloy iron core distribution transformers is no danger of fire extinguishment that can be installed in the load center decentrally and fully close to the fire point, thereby reducing the cost of the line and saving the cost of expensive low-voltage facilities.

H15-100~2500_10 Series Amorphous Alloy Dry-type Transformer.webp)

10-30~5000_20 Series Dry-type Transformer.webp)

10, SC(B)11-30~4000_10 Series Dry-Type Transformer.webp)

Leave A Comment