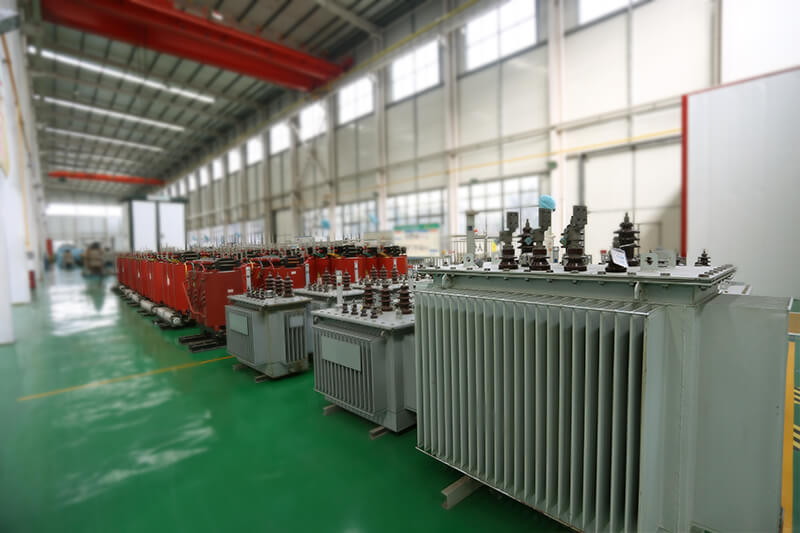

The description of S11-oil immersed transformer

S11-oil immersed transformer can be divided into iron core transformers and iron shell transformers. If the winding is wrapped around the core, it is an iron core transformer. If the winding is wrapped around the core, it is an iron shell transformer. The two are only slightly different in structure and there is no essential difference in principle. Power transformers are all iron-cored.

The S11-oil immersed transformer is mainly composed of iron core, winding, fuel tank, oil pillow, insulation sleeve, tap changer and gas relay.

The materials of S11-oil immersed transformer

Iron core of S11-oil immersed transformer

The iron core is the magnetic circuit part of the transformer. During operation, heat is generated due to hysteresis loss and eddy current loss. In order to reduce heat loss and volume and weight, the core of S11-oil immersed transformer is made of cold-rolled grain-oriented silicon steel sheet with a high magnetic permeability of less than 0.35mm. According to the arrangement of windings in the iron core, there are iron core type and iron shell type.

In large-capacity transformers, in order to make the heat generated by the core loss can be sufficiently taken away by the insulating oil during circulation to achieve a good cooling effect, a cooling oil channel is often provided in the core.

Winding of S11-oil immersed transformer

The windings and core are the core components of the transformer. Due to the resistance of the winding itself or the contact resistance at the joint, it is known from Joule's law that heat is generated. Therefore, the winding cannot pass a current higher than the rated current for a long time. In addition,S11-oil immersed transformer can be damaged by short-circuit currents that generate large electromagnetic forces on the windings. The basic winding has two types: concentric and overlapping.

The main faults of S11-oil immersed transformer windings are shorts between turns and shorts to the case. Interturn short-circuit is mainly caused by insulation aging, or due to transformer overload and mechanical damage to the insulation during traversing short-circuits. When the oil level in the transformer drops, inter-turn short circuits can also occur when the windings are exposed to the oil surface. In addition, when there is a cross-over short circuit, the windings are deformed due to the effect of overcurrent and the insulation is mechanically damaged and inter-turn short circuits can occur. In the case of an interturn short circuit, the current in the short-circuit winding may exceed the rated value, but the entire winding current may not exceed the rated value. In this case, the gas protection is activated. When the situation is severe, the differential protection device is activated. The short circuit to the shell is also caused by aging of the insulation or oil dampness, oil level drop, or lightning and operating overvoltage. In addition, when a short-circuit occurs in S11-oil immersed transformer, the winding will be deformed due to overcurrent and a short-circuit to the case will also occur. When the case is short-circuited that is generally the gas protection device action and the ground protection action.

Fuel tank of S11-oil immersed transformer

The body (winding and iron core) of the oil-immersed transformer is installed in a tank filled with transformer oil, and the tank is welded with steel plates. The fuel tank of the medium and small transformer is composed of a tank shell and a tank cover. The body of theS11-oil immersed transformer is placed in the tank shell and the tank body can be lifted out for maintenance when the tank cover is opened.

Insulation cooling of S11-oil immersed transformer

It can be divided into oil-immersed transformers and dry-type transformers. In order to strengthen the insulation and cooling conditions, the core and windings of the S11-oil immersed transformer are immersed together in a tank filled with transformer oil. In special cases, such as street lamps and mine lighting, dry-type transformers are also used.

Oil-immersed type

1. Non-enclosed oil-immersed transformers: There are mainly S8, S9, S10 and other products, which are widely used in industrial and mining enterprises, agriculture and civil buildings.

2. Enclosed oil-immersed transformers: There are mainly S9, S9-M, S10-M and other series products, which are mostly used in places with many oil pollution and multiple chemical substances in the petroleum and chemical industries.

3. Sealed oil-immersed transformers: mainly BS9, S9-, S10-, S11-MR, SH, SH12-M and other products, which can be used for power distribution in industrial and mining enterprises, agriculture, civil buildings and other places.

In addition, there are various special purpose special transformers. For example, high-voltage transformers for testing. S11-oil immersed transformer for electric furnaces, transformers for welding and transformers used in thyristor circuits are used for measuring instrument voltage transformers and current transformers.

Leave A Comment